Some answers to frequently asked questions about wheels. If you need more help, please get in touch.

Q: How do I know which rim size or tyre size I need?

Visit our Home page and click on the handy wheel/tyre calculator and information guide.

In general:

The alloy wheel size is shown as follows: Wheel diameter x Wheel width - e.g: 15 x 6.5J

The width is the section between the tyre mounting flanges on the wheel / The diameter is the overall diameter of the wheel.

It is important to bear in mind that when you alter the wheel size, the tyre size will also need to be changed to compensate. You need to keep the overal diameter of the new wheels & tyres within tolerance of the original wheels & tyres, so when you increase the wheel size, the tyre profile (side wall height) will decrease to balance out. We recommend a tolerance of no more than 2.5% difference in overall diameter.

Also wheel width is a consideration as there is a limit to how wide you can go on the vehicle before running into problems.

Q: What is the PCD of a wheel?

This is the diameter of an imaginary circle drawn through the centre of the bolt holes. The PCD of the wheel should match the PCD that your car came with as standard.

PCD is measured in mm. e.g: 4x100 means the wheel has 4 bolt holes and the diameter of the imaginary circle through the bolt holes is 100mm. These details are shown in the 'Wheel Specifications' section on the main product page.

It is a common misconception that all 4 stud wheels will fitment onto a 4 stud vehicle, but it is also down to the stud distancing.

Whilst a wheel will generally have the corresponding number of bolt holes for the vehicle, there are some wheels that are cross-drilled. This means that they will have either 8 of 10 bolts holes, of which half of these will be applicable to the intended vehicle but the other half will have a different stud spacing intended for alternative vehicles. This is a great feature if you plan on selling the wheels in the future of using them on a different car (as long as the stud configuration is correct).

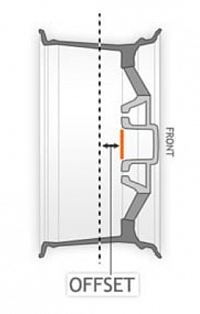

Q: What is meant by the wheel offset?

The offset determines how far under the arch or how far towards the outer arch a wheel will sit. Each car has its optimum offset and a range within which the offset can be for the wheel to fit the car properly.

If the offset is too low for the range allowed, the wheel could stick out from the side of the car, if too high from what it should be the wheel may catch on the suspension or bodywork as it will be too far under the car.

This is due to the fact that if you put a wheel on your hub with a higher offset than before, the wheels bolting face will have to move further under the car to meet the hub, in extreme cases causing the wheel to sit too far under.

If you take a wheel and cut it in half and draw a line down the centre of the width of the alloy wheel the offset will be the distance between the back face (mounting face) of the wheel and the centre line that you have just drawn.

The offset is commonly shown as the letters ET followed by a number, eg: ET49. The offset is always measured in mm and can normally be found stamped on the back of the wheel or behind the centre cap (if fitted).

Using Wheel Spacers to alter the offset:

If the offset of a wheel is too high for your vehicle, in most cases spacers can be used to reduce the offset, pushing the wheel further out to make it sit correctly in relation to the cars bodywork and arches. This allows you to fit wheels to your car that aren't initially made in a direct fitment, widening your choice of wheels and is completely safe and road legal to do. However, if the offset of a wheel is too low compared to the offset your car needs, there is no way of rectifying this as they will already sit too far out from where they should be and can't be brought back under the car.

Q: Explain wheel centre bore and spigot rings.

This is the diameter of the centre hole in the back of the wheel. It is crucial that the centre bore of the wheel locates properly on the lip on the hub of the vehicle to get a perfect fit. Most wheels work on a spigot ring locating system because most wheels have a centre bore bigger than the size of the hub lip allowing them to fit a wider range of cars. A spigot ring is fitted into the back of the wheel with an outer diameter the size of the centre bore, and an inner diameter the size of the hub lip to allow the wheel to be correctly located onto the hub and to fit tightly onto the vehicle for safety and comfort.

There are wheels that are hub-centric i.e. the wheel is manufactured with a centre bore to fit precisely onto a specific vehicle and in these cases we would not supply spigot rings as they would be unnecessary.

If the wheel does not locate onto the vehicle's hub assembly correctly it will cause a vibration on the steering wheel and can lead to bad wear on the tyres and bearings so if spigot rings are provided you MUST use them.

Q: What are FFT wheels?

Flow Form Technology wheels are manufactured using a highly advanced production technique called flow forming. The rim of the wheels is forged at high pressure while the wheel is spun at high speed. This alters the molecular structure and enhances the strength of the alloy. The benefit is a much lighter weight than a regular cast wheel. Most importantly, the weight saving is in the outer rim of the wheel which dramatically reduces rotational mass and enhances vehicle performance.